For instance, an IV set is designed to carry liquid or a slurry of medicines into the bloodstream. A variety of components are used to complete the set, including cannulas, tubing, spikes, clamps and tubing connectors. These components are manufactured through molding processes. They are then sub-assembled into various sub-assemblies. Eventually, the set is assembled into a fully-packaged pouch. The pouch is then sterilized in a sterilization plant.

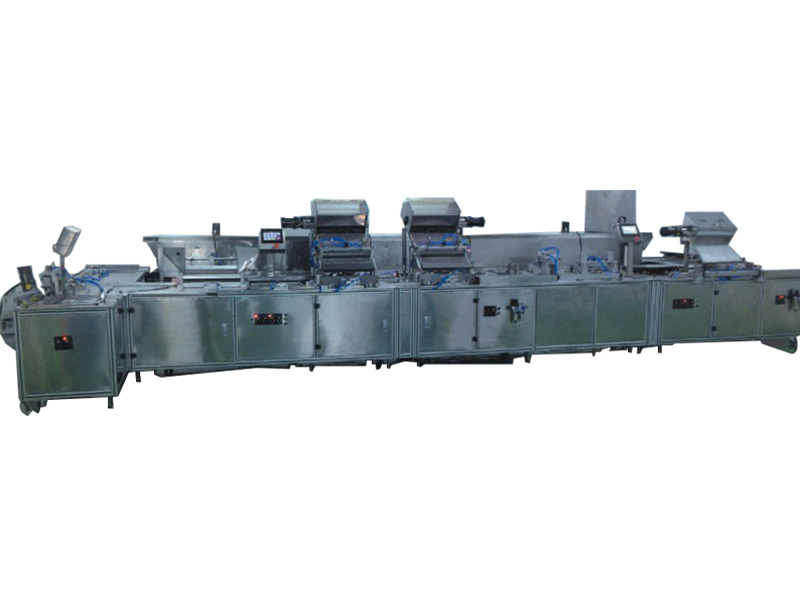

The invention relates to an infusion set assembly machine. It is an automated system that can assemble several parts of an Infusion Drip Chamber into a single pouch. The machine uses a ribbon bundling heat sealing mechanism to improve production efficiency.

The ribbon bundling heat sealing mechanism consists of a first clamping component, a second clamping component and a heating component. The ribbon end is abutted by the heating component to create a seamless seal. This mechanism is an effective way of tying up the transfusion device. It is also a clever use of energy, which is the main function of the heating component.

The infusion set assembly machine is a bit complicated, but it has some merits. For instance, the ribbon bundling heat sealing mechanism is an effective way of tying the transfusion device up. The band tied up by the band on the machine can tie the device up very quickly.

English

English русский

русский 中文简体

中文简体