The YJKP is a cost-effective servo press kit. It includes a few of the standard electric and pneumatic drives and controllers. It is able to press out 17 kilonewtons of force, which is more than enough to assemble an insulin pen. It also includes a preconfigured modular system to save time and money. It also features three press-fitting steps.

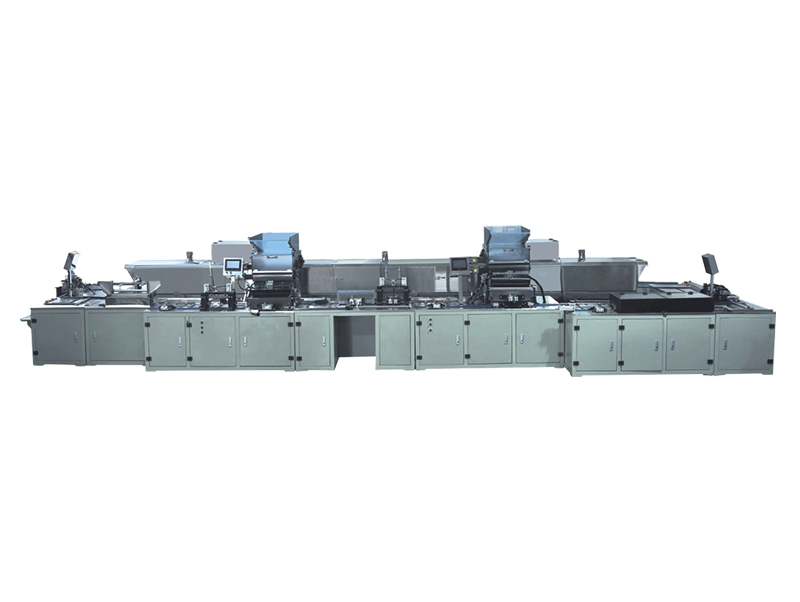

The KF-1 Insulin Needle Assembly Machine is a solid choice, with a high level of automation and a low level of noise. The system has a high assembling speed and a built-in raw materials lifting machine. It is also equipped with an automatic syringe feeder to ensure accurate insertion and retrieval of the syringes.

English

English русский

русский 中文简体

中文简体