Another method involves fixing the cannula and stylet in the hub. In this assembly, the stylet and cannula are ground at the same time to form a mating pair of points.

Another method involves inserting the stylet into the cannula until it is aligned. This assembly can be fabricated by a plastic molding company. It can be sold at competitive prices.

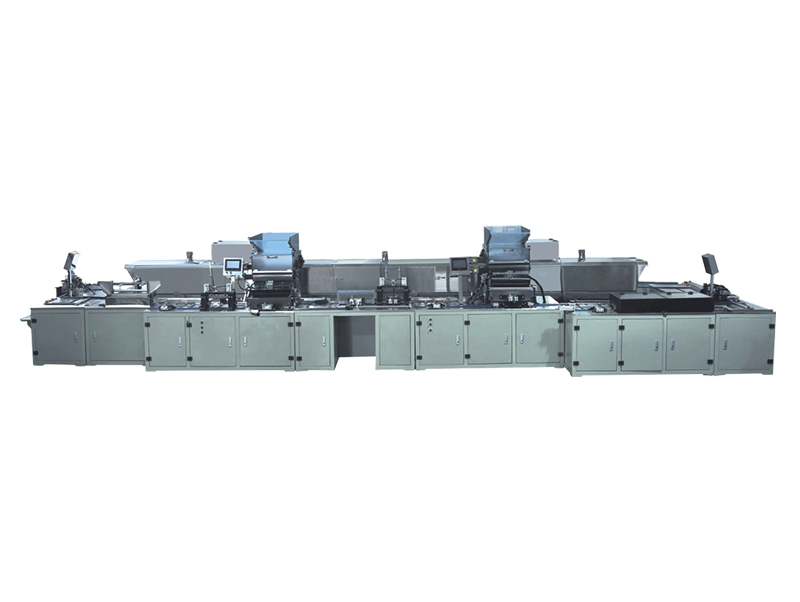

The present invention provides a simple and inexpensive means of fabricating a needle assembly. It saves time and eliminates expensive manual labor. It is suitable for use with syringes and other medical devices. It is also suitable for use in ISO 8 clean rooms. It is compact, can operate in-line and off-line, and meets safety standards.

The cannula can be made from a metallic or non-metallic material. Typical materials include stainless steel. The end of the cannula can be flat cylindrical or beveled. The distal end of the stylet and cannula are usually ground to form a matched pair of points.

The needle assembly of present invention comprises a cannula and a stylet with a cap fixed to the proximal end of the stylet. The stylet includes a locating knob on one side and a locating bump on the other. The locating knob and locating bump are adapted to mate with the locating means on the hub.

Injection Needle Automatic Assembly Machine

English

English русский

русский 中文简体

中文简体