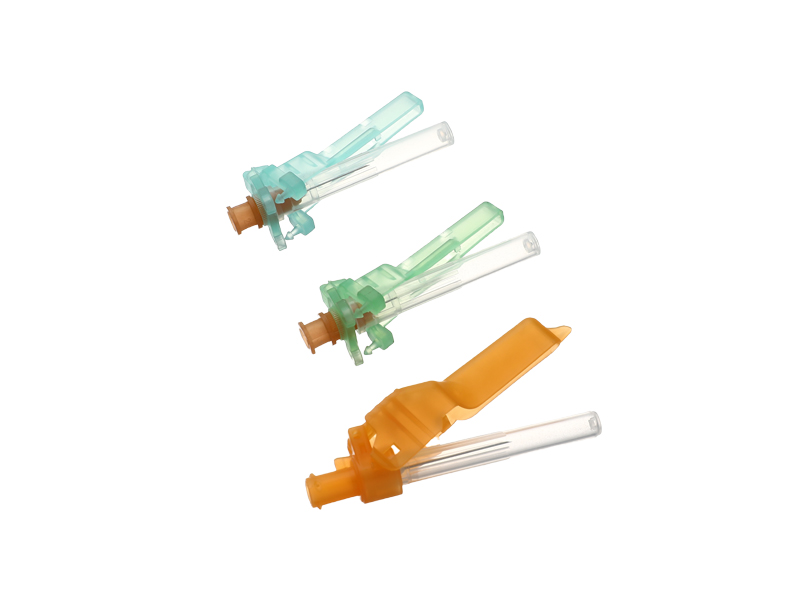

Safety injection needles are made from elastomeric plastic material. This material is designed to give the needle its flexibility, while also having built-in elasticity. The safety injection needle is designed to meet TRBA 250 regulations.

Pen needles include a double ended needle cannula, which is enclosed in a cup-shaped cap. This cap can be removed before use. This cup-shaped cap is also used for disposal of the double ended needle cannula assembly. The cup-shaped cap is typically threaded. The natural tendency of the user is to press the cap towards the injector during assembly. This may cause the cap to pierce the needle during assembly.

Pen needles also include a hub assembly, which is generally tubular. The hub assembly includes an internal circumferential groove for fitting the collar. The collar is mated to the needle hub through the internal circumferential groove. The collar includes a luer end for mating to the syringe and an indicating area.

The safety injection needle also includes a locking mechanism. The locking mechanism includes a hook and resilient detents. The hook grips onto the shaft of the cannula when the housing is pivoted to an alignment position. The resilient detents catch the hook-shaped end portions of the locking fingers during extension. This assures that the safety shield will lock in an extended position after injection.

English

English русский

русский 中文简体

中文简体