The growth of the diabetic population is increasing by approximately 10 million each year. Hence, insulin pens are becoming increasingly important for the management of diabetes. The OEM systems builder Syntegon Technology developed a flexible production line concept with YJKP servo press kit. In addition, servo press kit and Festo automation help make the production line efficient and flexible.

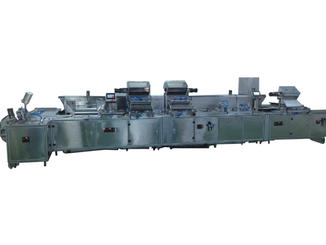

Insulin assembly machines are also available from Korea. A fully automated insulin pen assembly machine can assemble as many as 70 pens per minute. This machine is designed for the manufacturing of insulin pens and other medical devices. It has numerous applications, including diabetes care, autoimmune disease, hormone replacement therapies, and emergency medicine.

English

English русский

русский 中文简体

中文简体